When choosing a UPS system, obvious features such as its capacity, battery autonomy, availability, economy and resilience to failure will be weighed up first. Maintenance contracts will most likely be discussed as well. However, while these factors are essential, careful consideration should also be given to the practical aspects of setting up a new UPS.

In this article Tan Yu Ming, general manager at KOHLER Uninterruptible Power, looks at these practical aspects, showing the importance of their role in the UPS installation’s ultimate success.

Whenever a designer specifies an uninterruptible power supply (UPS) for their critical data centre or office load, their first priorities will logically relate to the functionality and performance of the UPS itself; does it have sufficient capacity and battery autonomy for the load’s requirements? Does it offer high enough availability and sufficient resilience to faults? Will TCO be reasonable, together with a sufficiently green footprint – and can the system easily be scaled for future expansion?

While these are perfectly legitimate and indeed critical considerations, there are other factors that are less publicised but nevertheless equally critical to the ultimate smooth performance and success of any UPS installation. These relate to the practical aspects of setting up a UPS, from its initial transport and delivery to site, through to installation and commissioning, and then arranging an effective preventative maintenance and emergency response contract.

In the article below, we focus on the setup factors in chronological order, so that their role in the UPS installation’s ultimate success becomes clearly visible. We start by preparing for delivery of the UPS equipment, and move forward from there.

Weight and space considerations

In fact modern UPS systems allow considerably more latitude in delivery than their earlier counterparts, as they are far more compact and lightweight; bulky and heavy input transformers have been eliminated. Systems such as KOHLER Uninterruptible Power’s PW 5000/TP can deliver up to 50kVA from a 0.4 m² footprint, so are fairly straightforward to handle. As capacity, size and weight increase, though, more careful planning is required. Irrespective of their size, UPS systems contain computer-type electronic components that require protection during transport. The UPS supplier should be able to recommend experienced removal contractors who can offer the air-ride suspension vehicles and specialist lifting equipment necessary.

Fig.1: PW 5000/TP compact UPS with minimal footprint

The target location should be sufficiently sized for immediate UPS delivery, and for future expansion as well. While modern modular UPS systems facilitate scalability without impacting on footprint by allowing modules to be added to an existing frame, further expansion may eventually call for more frames to be installed.

While resolving sizing issues, the location should also be checked for other aspects of suitability. The floor must be able to bear the weight of the equipment, which should be positioned to avoid disruption and concern to nearby staff and business operations. At the same time, access to the equipment for servicing should be easy and convenient. The environment should meet any requirements specified by the UPS manufacturer, while the UPS installation itself should have minimal impact on air conditioning systems and airflow.

Other points to consider when siting the UPS include providing a safe, adequately sized location for the battery set, and the accommodation of any controlling switchgear.

Cabling and electrical installation

Once the equipment has been located on site, attention can turn to cable entry and termination. Most medium to large UPSs require bottom cable entry; this must be accommodated whether the system is to be installed in a plant room, which typically has a solid floor, or a computer room, where raised floors are more likely.

For a solid floor, a trench can be cut to lay the input and output AC cables and battery DC cables, and run them beneath the cabinet for connection to the UPS terminals. Alternatively, the UPS cabinet can be mounted on a steel plinth of sufficient height to allow satisfactory cable bend radii through 90°. This is particularly important for sizeable UPSs with large cross sectional area cables.

Computer rooms often have raised flooring, permitting containment and access for computer equipment network and power cabling, and sometimes to facilitate underfloor cooling. These provide convenient routes for the UPS power and battery cables, which can be brought into the UPS cabinets via bottom access. The UPS’s weight, especially if it contains batteries, may be enough to require a steel plinth to distribute the load. The plinth stands on the subfloor and is adjusted until its upper surface is flush with the raised floor surface.

Performing the electrical installation is a task for experienced and qualified electrical contractors, employed either from recommendation or by the UPS supplier. In either case, references and evidence of previous successful installations should be sought and obtained. All installation work must be carried out in strict accordance with the manufacturer’s instructions and strict compliance with prevailing local electrical installation legislation.

The electricity supply required by high power UPS equipment will have a significant impact on the existing cabling and switchgear, so careful integration with these will be necessary. However, detailed planning at this stage will be rewarded by time and cost savings in the future if it ensures adequate provision for any potential business growth and extra UPS capacity. An integrated, purpose-designed panel incorporating input and output switchgear for each UPS cabinet, together with a system isolator and wrap-around bypass switch can reduce the system design burden, simplify cabling and shorten cable runs. It also minimises design and implementation complexity, saving time and costs.

When designing the power feeds from the UPS units to the distributed components of the critical load, it is important to choose electrical circuit routes and circuit breaker sizing that provide satisfactory discrimination downstream of the UPS system. This is to ensure that a single load fault only trips its local protection device, without unnecessarily shutting down wider sections of the power system and needlessly losing productivity.

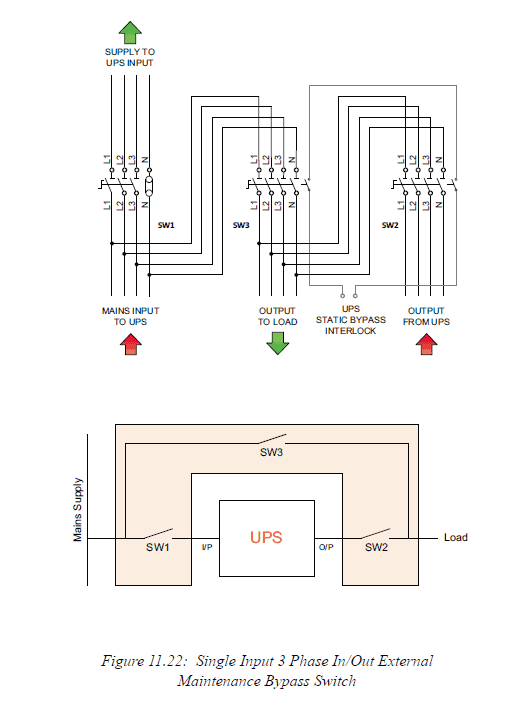

An external maintenance bypass switch should also be provided, allowing the entire UPS system to be physically and electrically isolated for a swap-out or move without interrupting power to the load. Also, to ensure personnel safety and equipment protection, correct earthing is essential. All earthing points within the UPS circuits must be connected to a properly planned and secure earthing system.

Fig.2: Single input three-phase in/out external maintenance bypass switch

Commissioning and load bank testing

These steps to UPS installation should be complemented by equal care with commissioning. The small additional investment necessary to use the UPS supplier’s trained and experienced technicians is more than offset by a number of benefits. These include a thorough check of the entire system installation, acceptance of environmental conditions and complete warranty cover on all UPS equipment. All equipment serial numbers will be registered with the supplier, and the UPS user will be trained in the operation of their system.

Load bank testing should be used to validate operational performance and prove battery autonomy under full load. It is recommended to perform the load bank test one week after commissioning as voltages across the battery blocks have equalised and the battery is fully charged.

Conclusions

The steps above are logical, and, provided qualified technicians are available, simple to perform. However in KOHLER Uninterruptible Power’s experience of helping customers specify and install UPS systems, they provide a vital complement to the UPS’s technological features in establishing a successful and durable power protection solution.

Accordingly, from a project’s outset, discussions between UPS users and potential suppliers should encompass not only the equipment’s technical specifications and maintenance support contracts, but also the practical aspects of how the UPS system is to be set up on the user’s premises, and how the supplier can advise and help with this process.