UPS generators are no longer just a backup plan. Today, they are considered a vital component of a company’s power protection policy, as sizing UPS batteries for protracted power blackouts is simply uneconomic and impractical.

In choosing a generator for a data centre or other critical IT load application, a number of factors must be considered. These include the generator’s key components, environmental issues and the qualifications of the suppliers as well as compatibility with the UPS to be supported.

In this article, Alan Luscombe, director at KOHLER Uninterruptible Power, a KOHLER company, discusses how generators work with uninterruptible power supplies, and the factors you must consider when choosing a generator as part of your power protection policy.

Following a power outage, a UPS system with true online topology will be able to supply all the protection required – even for the largest, most critical loads, if sized correctly. The UPS dual power conversion technology is designed to filter out mains-borne disturbances, while the batteries maintain power during the initial blackout period. However, a UPS alone will not be sufficient if the blackouts are likely to protract and extend beyond the battery autonomy of the UPS. Extending battery autonomy to hours rather than minutes can be prohibitively expensive, especially as there is little value in powering a critical load but not its cooling system.

UPS and generators working together

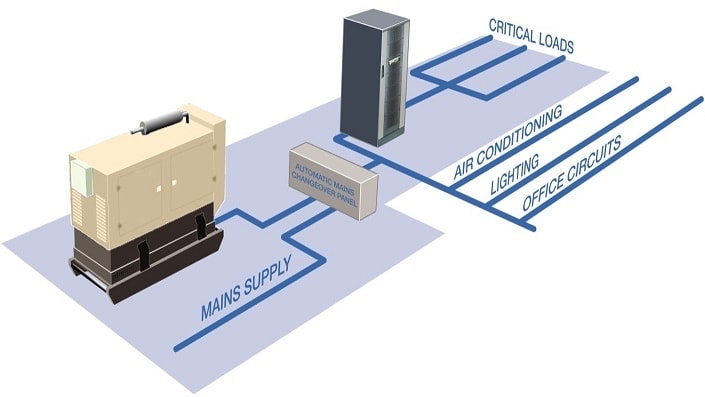

In some applications, it may be acceptable to use the battery autonomy to gradually reduce the load if the blackout time is extended. However, for critical applications that must remain up and running through power blackouts of any length, a matched UPS-generator arrangement becomes the only practical solution. To ensure continuity of power throughout a blackout event, UPS, generator and an Automatic Mains Failure (AMF) Detection panel are needed to work together. When the mains initially fail, the UPS batteries support the load during a pre-set AMF delay time. If this period expires, the generator starts up and the UPS detects the generator power, using it to feed the load and recharge the depleted batteries. The generator runs until mains power is restored and stabilised, and is then shut down under AMF control while the UPS reverts to mains. UPS battery power covers the short power interruption during this transfer.

A backup generator set comprises a stored energy source, an engine, an alternator, a control panel and the AMF panel. Although both gas and diesel powered engines are available, standby generators are normally diesel-powered. Engine suppliers include John Deere, Volvo and Mitsubishi, for which different control panels with varying capabilities are available. Standard types provide automatic and manual generator control while providing the basic indication of operational parameters, which includes voltage, frequency, coolant temperature, oil pressure and battery voltage, plus alarm and fault indication. More advanced panels offer more sophisticated user interface displays and enhanced diagnostic capabilities. Remote monitoring and control via Ethernet, RS485 or USB ports as well as fault-finding and alarm diagnostics are also possible.

Fig. 1 PW J Series – 22–250kVA John Deere Generators

Fig. 2 PW T Series – 5–44kVA Mitsubishi /Diesel Generators

Fig. 3 PW V Series – 250–650kVA Volvo Diesel Generators

Whichever configuration is chosen, generators must be compatible with the UPS and all other power equipment to guarantee an uninterrupted power supply. Ensuring compatibility can be considerably simplified by sourcing UPS and generator from a single supplier, who offers proven, matched generator/UPS sets. An issue can be the generator output frequency. If its range is outside the UPS’s tolerance, the UPS cannot synchronise with the generator without endangering its load. This problem can be avoided if the generator is known to be UPS-compatible and fully tested.

Practical generator considerations

When sizing the generator, it is important to consider more than just the UPS and its critical load. Cooling equipment for the load as well as emergency lighting, communications and alarm systems must all remain operational when it comes to a power failure. As a rule of thumb, the generator should be sized at one and a half times of the nominal UPS capacity for transformerless UPS systems. Additionally, three times the nominal air conditioning capacity should be provided.

Since power failures are unpredictable, the generator must always be ready to start and support the load. Accordingly it must be kept warm, with a fully charged battery and sufficient fuel. It must also receive mains status signals to initiate its start-up and shutdown. Standby generators are kept warm by mains-powered engine water heaters or jackets. Mains are also used to trickle charge the battery. The status signals to initiate starting and stopping of the mains, is provided by an AMF panel. Another important factor is that the back-up generator has an electronic governor to ensure highly responsive control of engine speed and output voltage frequency.

Any supplier that performs UPS and generator installations should offer advice and provide solutions related to important environmental issues and comply with regulations for safe fuel storage. Suitable noise attenuation housings have to be used to limit noises, especially since generators may have to run at night. Heat generation must be managed, with generators often sited outdoors in weatherproof enclosures. Provision must also be made for safe, unobtrusive removal of exhaust fumes.

This article has explained why UPS/generator combinations provide the only practical protection from extended blackouts for critical loads, and described how generators and UPSs work together to provide an uninterrupted power supply throughout a blackout event. Practical considerations relating to UPS/generator compatibility, sizing, readiness and environmental concerns are also covered.