A UPS must warn all ICT equipment it supports of any power failure, to allow the possibility of an orderly shutdown. UPS communications capability also brings other benefits, including management of multiple UPS installations and delivery of data for preventative maintenance and fault diagnostic applications. Authored by Matt Henley, Technical Service Manager for KOHLER Uninterruptible Power, a KOHLER company, this article looks at how UPSs can communicate alarm and status information locally or transfer it onto an enterprise network for distribution through and beyond the operator’s organization.

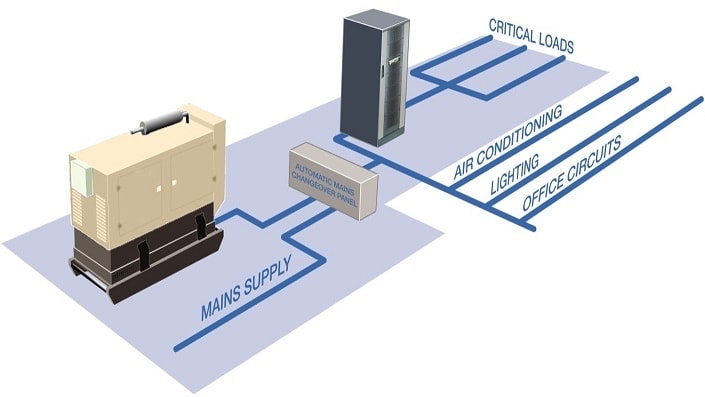

UPSs provide essential uninterrupted power during a mains disturbance or failure. If the mains supply drops below the critical load’s voltage tolerance limit, the UPS’s battery seamlessly maintains power to the load. However, while UPS battery autonomy is typically 10 – 30 minutes, power outages of an hour or more are not unknown in the UK. If the battery autonomy is exceeded, loss of power to the load will merely be delayed rather than prevented – and if the load includes ICT equipment, the consequences of such an outage can far exceed the time lost during the event: Hardware may be permanently damaged, and worse, data can be destroyed.

Therefore, when the critical load includes ICT or other sensitive equipment, it’s vital that the UPS’s battery autonomy is complemented by its ability to communicate the mains failure event, and its own status, to any relevant equipment. A standby generator, if available, has its own sensing for mains failure, it stabilises and synchronises with the UPS within the battery autonomy time. In the absence of a generator, a power fail warning allows the ICT equipment to shut down automatically, gracefully and safely.

However a simple ‘power fail’ signal would be insufficient, because no-one wants a generator to start up or a computer network to shut down unless the mains event really warrants it. Therefore, the simplest practical UPS communications comprises a set of volt-free alarm contacts. The first signals that the UPS is running on battery and the second signals when the battery reaches a predetermined low level. The client ICT system reacts to the first signal by starting a timer, which resets if mains power is restored. If the timer times out, or if the ‘low battery’ signal is received, the client system initiates a managed shutdown.

Using volt-free contacts to obtain UPS information is attractive because of their simplicity. Their ‘True/Not True’ information is limited yet sufficient for basic status and alarm indication. By contrast, RS-232 communications are a little more complex to implement, especially as each UPS manufacturer has his own RS-232 protocol. However more sophisticated monitoring and data exchange becomes possible, so users frequently decide to utilise the RS-232 port provided by many UPS manufacturers. More detailed information, and analogue values can be transmitted and displayed remotely. Examples include inverter output voltage, frequency, current, kVA and kW, battery voltage, charge/discharge current and remaining battery life, statistics regarding mains failures and UPS operation, and many more measured or calculated results. These values, like the basic alarm information, can be obtained in real time.

How the information from the UPS is displayed on a remote computer depends on the monitoring software provided by the UPS manufacturer. A graphical display of UPS status, voltage, current, load, battery voltage, frequency and other parameters is possible. Configurable responses to certain alarms can be set up and broadcast to users, and scheduled diagnostics checks with data logging can be run. RS-485 or RS-422 links can be used to achieve longer communication distances. RS-422 is preferred as it is full duplex, and usually easier to set up than RS-485. USB ports are now frequently offered as another possibility for real-time UPS monitoring.

The UPS alarm and status information – whether derived from volt-free contacts or a serial port – achieves maximum availability, distribution and use if it can be transferred onto an enterprise network. This allows the UPS information to be transported around the site, to remote sites and to other organisation locations such as the UPS manufacturer’s diagnostics and maintenance facility. The UPS is usually connected onto the network using an SNMP adapter or card, which can accept serial communications or volt-free contact inputs. The adapter converts the UPS information into standard protocols that can be understood by the other network devices. These typically include HTTP, SNMP, SMTP, WAP, Telnet, SSL and SSH.

Network-level availability of UPS information is essential for management of larger sites with multiple UPS installations. For example if one redundant UPS unit in a parallel redundant configuration fails, a system shutdown is unnecessary and should not be initiated. In general it should be possible to monitor and manage the entire UPS configuration at a system rather than modular level. Most UPS manufacturers offer suitable software, which can be chosen to run under Windows, Apple, Linux or Unix environments. Because SNMP is an established and accepted standard, UPSs from different manufacturers can be added to the enterprise network and integrated into the monitoring and control software.

UPS communications are invaluable not only for handling mains disturbance events, but also in providing data for improved load management efficiency, preventative maintenance and failure diagnostics. Information can be delivered to site operating staff or UPS maintenance specialists via network terminals, web pages, emails, mobile phone or SMS messages. UPSs become visible and manageable as an integrated set of on-line devices.