Today, data centre and IT systems operators can face unpredictable ICT load growth that threatens their budget and available floor space; at the same time, they have to contend with sharply increased energy costs and legislative pressure to be increasingly green. Fortunately, modern transformerless UPS systems can help offset these negative pressures in several ways, due both to the underlying technology and its implementation within the product.

In this article, Kenny Green, technical support manager at KOHLER Uninterruptible Power, a KOHLER company, discusses the factors that have enabled transformerless technology and how it is implemented. He then reviews the energy, cost, space saving and scalability benefits it offers its users.

Today, data centre and ICT system operators face multiple pressures: Demand for data processing capacity is growing rapidly, while the costs of providing this capacity are increasing sharply. An effective energy strategy will help to ease this scenario, partly by controlling ever-rising energy costs, but also by addressing today’s legislative, social and ultimately financial pressure to ‘go green’.

Space efficiency is also increasingly important, as operators seek to pack expanding volumes of data processing equipment into limited floor area. These pressures are exacerbated as the rate of growth can be difficult to predict. How can you plan effectively for future growth if you’re not sure exactly what its rate will be?

Today, uninterruptible power supplies (UPSs) are essential to any significant data centre or ICT facility. They must be large enough to handle all the critical equipment’s power. Any energy or space saving achieved for the UPS contributes significantly to the efficiency of the entire facility.

With these considerations in mind, it is worth investigating the benefits offered by modern, modular UPS technology. This is because these benefits lead to not only improved energy and space efficiency, but also to powerful scalability and efficient management of rapidly changing capacity demand.

Transformerless technology

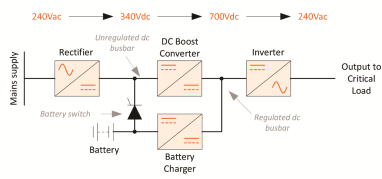

When static UPSs began appearing in the seventies, they utilised an internal transformer to step up the output voltage to the critical load – not, as commonly believed, to provide galvanic isolation. Transformer-based systems were very widely produced, especially for the highest power applications. However, advances in power semiconductor technology, particularly the introduction of the Insulated Gate Bipolar Transistor (IGBT) device have made the transformerless UPS a viable proposition. Fig.1 shows a transformerless UPS design in which a fixed rectifier uses a DC converter to boost its DC output to a high level. With this level, the inverter can directly produce an output RMS voltage compatible with the rectifier input supply, and the requirement of the critical load.

Fig. 1: Transformerless UPS block diagram

If the mains supply fails the battery is instantly connected to the unregulated DC busbar by an electronic switching device such as a fast-acting SCR. The DC boost converter continues to supply the regulated DC busbar, so power to the critical load remains uninterrupted. As with transformer-based designs, a long-term power blackout will eventually exhaust the battery and shut down the inverter.

Transformerless topology has largely taken over from traditional transformer-based designs because of the many advantages it offers. Above all, it delivers improved efficiency from a considerably smaller and lighter form factor, while a number of further benefits also apply.

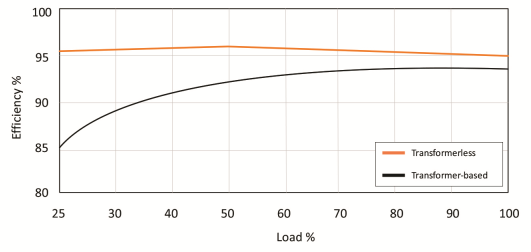

Fig.2 shows the scope of the efficiency benefits, which extend over the entire load spectrum. Overall, efficiency is improved by around 5%, which yields substantial reductions in both direct energy costs and indirect cooling costs.

Fig.2: UPS transfer efficiency curve

Transformerless UPS systems also present a higher input power factor than their transformer-based equivalents. The phase-controlled input rectifier used within the transformer-based systems has a lagging input power factor which falls further from unity as the UPS load reduces. By contrast, transformerless topology utilises a free-running rectifier and a DC – DC boost converter with very high-frequency switching; these factors produce an input power factor inherently much closer to unity and less load-dependant than the transformer-based UPS. Moving the power factor towards unity reduces input current magnitude; this reduces cabling, switchgear sizing and possibly electrical energy costs.

The transformerless UPS’s free-running full-wave bridge rectifier also allows a reduction of total input current harmonic distortion (THDi) in a three-phase UPS from 30% to less than 3%. This limits harmonic emissions and makes a considerable contribution to meeting the Energy Network Association’s recommendations for electromagnetic compatibility between an electricity supply system and the equipment it feeds.

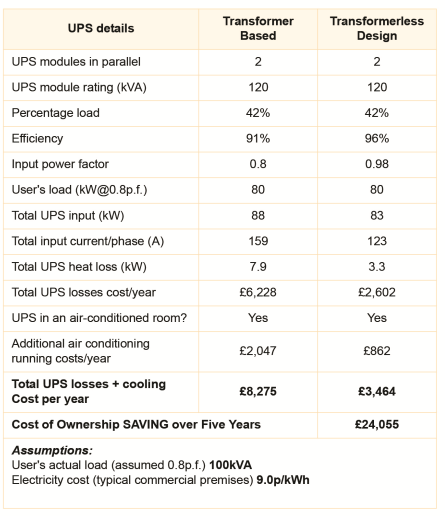

The opportunity to reduce operating costs can be demonstrated by an example. Consider a 100kVA load, supplied by a parallel redundant UPS system comprising two 120kVA modules. Fully redundant power protection is being provided as each module can completely support the load if the other fails. However the arrangement also means that during normal operation the modules share the load equally and each runs at just 42% of its rated capacity. This takes them to a relatively disadvantageous point in their efficiency curve. Fig. 3 below compares the implications of this for transformerless and transformer-based UPS implementations.

Fig. 3: Comparison of costs between transformerless and transformer-based UPS solutions

Note that the transformerless implementation runs at 96% efficiency, while its transformer-based equivalent achieves just 91%. As a result, the transformerless UPS’s energy bill – including both direct losses and cooling costs – is less than half of the transformer-based UPS’s. Over five years, this could produce over £24,000 total energy cost saving.

Modular UPS systems and scalability

As mentioned earlier, eliminating the transformer allows considerable savings in size and weight as well as energy. As we shall see, this has profound implications for UPS topology and scalability. Because the newer design actually eliminates the need for a 12-pulse rectifier as well as the transformer, the 120kVA UPS of our example above weighs little more than a quarter of its transformer-based equivalent; 310 kg compared with 1200 kg. Meanwhile, its footprint reduces from 1.32 m2 to 0.64 m2.

Clearly these physical reductions are in themselves welcome in space-constrained environments. Yet they have ushered in a more profound development; the concept of UPSs as rack-mounted modules rather than free-standing floor units. This means that a single vertical cabinet could be installed into an ICT area and populated with one plug-in rack-mounting UPS module of an appropriate rating. A second module could be added either to achieve N+1 redundancy or to increase total UPS capacity. Later, if the demand for ICT resource grows, more modules can be plugged into the rack to instantly expand UPS capacity. This can be done without need for more floor space or extra cabling – and the whole upgrade can be performed without having to interrupt power to the ICT equipment.

For example, KOHLER Uninterruptible Power’s PW 8000DPA, 9000DPA and 9500DPA families implement these modular, scalable solutions at different power levels. PW 8000DPA modules rated at 10 or 20kVA each are available, while those for PW 9000DPA are rated from 10 to 50kVA, with PW 9500DPA using modules rated at 100kVA. This allows solutions to be scaled from 10kVA all the way up to 500kVA, simply by populating a single PW cabinet with appropriate modules. This is referred to as vertical scalability. Larger installations can also adopt a ‘horizontal scalability’ solution, comprising a number of cabinets paralleled together and populated to meet the total critical load.

Modern UPS, like the PW families, address the most urgent issues facing data centre and ICT equipment operators today: How to achieve great energy efficiency from a minimum floor footprint – and how to preserve these advantages while supporting unpredictable growth in demand for ICT resource.