All UPSs and associated system components need periodic maintenance and occasional parts replacements to ensure optimal reliability. They also need the security of an emergency call-out facility, as failures can occur in any electrical equipment, no matter how well-maintained it is.

In this article, Kenny Green, Technical Support Manager at KOHLER Uninterruptible Power, a KOHLER company, looks at these elements of effective maintenance. This review shows how such elements can contribute to an overall plan that assures the UPS system’s uninterrupted availability over periods of many years.

Most electronic and electrical equipment, no matter how well-designed and built it is, will fail eventually unless it is maintained according to its manufacturer’s instructions. On rare occasions, maybe after suffering adverse environmental conditions, even well-maintained equipment can fail.

Failure-induced downtime is unacceptable for any commercially-used equipment, but it’s particularly serious for UPS systems; if they go offline, they compromise all the equipment they have been installed to protect. Fortunately, there are a number of steps, at several levels, that UPS operators can take to minimize this exposure.

The highest-level steps to ensure availability include keeping the UPS in optimum condition within a clean, dry, tidy and well-lit area, and checking that all alarms and indications are recorded, logged and reported correctly. Responsibility for the UPS and its associated equipment should be assigned to a named member of staff, and a suitable maintenance contract negotiated with a reputable UPS specialist.

This maintenance contract should cover three key components: A regular testing and preventative maintenance schedule; emergency call-out facilities with a guaranteed response time; and a policy for end-of-life component replacement.

The maintenance schedule should be designed to include all the UPS installation’s major parts, which are the UPS itself, the battery and the generator if present. The schedule will be based on a planned programme of visits in which service technicians perform inspection and maintenance as required.

Regular UPS maintenance

For the UPS, meters and instrumentation should be checked for correct operation, and any meter readings checked, recorded and verified for accuracy. Local and remote monitoring panels and communications channels, as well as indicator lamps, should be checked for correct status indication. Switchgear and circuit breaker operation should also be proved.

Environmental conditions should then be reviewed, starting with actions as simple as removing any material and obstructions from around the equipment, and checking for any abnormal conditions. Ensure that airflow in and around the installation is unimpeded while changing any air filters that are due for replacement.

The equipment itself should be checked for evidence of excessive heat, noise or vibration, as well as signs of damage to components or to power and control wiring and connections. This includes looking for swelling and leakage on ac and dc capacitors. Power supply voltages and waveforms, together with the overall UPS operation, should be checked.

The service plan should also identify the degradation of any critical components, allowing repairs or replacement to be performed before a fault occurs. Backup spares should be available immediately on demand.

Battery inspection and maintenance

Traditional batteries such as open-vented lead-acid types could be checked using low technology methods such as visual inspection and voltage testing. These are not possible or effective with the Valve Regulated Lead Acid (VRLA) batteries found in most UPSs today. However, methods appropriate and effective to VRLA technology have been available for many years and are now widely used. The most important of these is battery impedance testing.

This approach depends on age-related changes in battery impedance. The internal impedance of a new battery is low, and measured in milliohms. As the battery ages its impedance increases marginally due to normal internal corrosion. For healthy batteries, this rate of increase should be uniform across the single and parallel arrays of serial battery strings that comprise them. Any battery, or group of batteries that shows an impedance increase higher than the others becomes suspect.

Battery impedance testing is useful and convenient, because it is easy to perform, and almost all battery problems manifest themselves as a rise in internal impedance. These include a loss of electrolyte due to venting through overcharging, leakage through seals, or sometimes migration of electrolyte between cells. Occasionally, excessive corrosion can cause loss of metal area or even disintegration within a battery. To perform the test, pass an AC current at a level related to the battery Ah rating through the battery; then use this value together with the millivolt reading across the battery terminals to calculate the internal impedance.

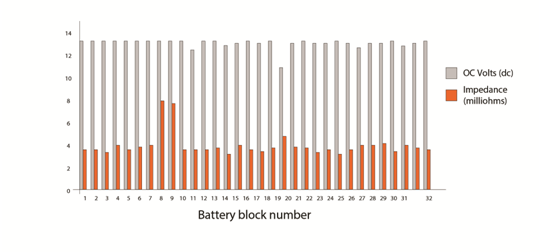

Regular impedance testing will track battery condition and allow accurate prediction of the end of the battery’s reliable working life. Results can be computer-generated, as shown in Fig.1. This chart, recorded near the end of a battery’s life, shows how impedance readings provide a better indication of problems than float voltage readings do. Impedance readings for blocks 8 and 9 are high, revealing problems not made visible by voltage readings.

Fig.1: Impedance graph for battery at end of its working life

Impedance testing has a useful complement in load bank testing; connecting an artificial full load to a battery and monitoring its performance during discharge. This is the only way of measuring battery capacity at the time of the test, and proving the integrity of all components and interconnections. It is a valuable tool, for example, to prove after commissioning that the battery will support the specified load for the specified time. However it should be used sparingly as it completely discharges the battery; the load is denied of full support until recharging is complete. Also, completely discharging VRLA batteries in this way reduces their life and carries some risk of permanent damage.

Permanently-fitted fixed battery monitoring systems provide another diagnostics solution. These allow continuous monitoring of battery voltages, current, temperature and impedance, and can detect differences between individual battery blocks during any charge/discharge cycles. As such systems are relatively expensive, they are used mainly in battery installations that are large or considered highly critical.

Generator and overall system checking

Generators, which are frequently part of a site power protection plan, should also have a regular service program. This should cover all major generator components, including the cooling, fuel and lubrication systems, the starting system and mechanical parts, and control panel. Insulation and load testing should also be performed.

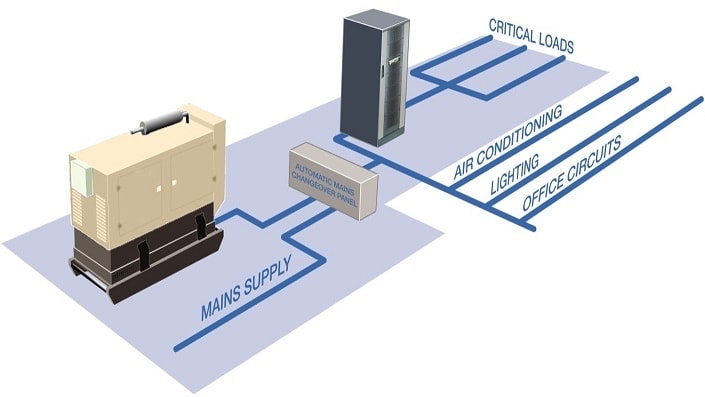

As well as planned maintenance of the UPS, battery and generator components, occasional testing of the entire system is also worth considering. This test could ensure that the automatic mains failure (AMF) equipment functions correctly, the generator starts properly, the UPS accepts output from the generator successfully and the batteries recharge normally.

Emergency call-out resource

Even good-quality, well maintained equipment can fail occasionally, so any scheduled maintenance plan must be complemented by an emergency call-out service. Different options should exist to allow UPS users to balance response levels against cost. Typically, telephone support will be available 24/7/365, while a guaranteed time within which a service engineer arrives on site following a call-out can be negotiated. Similarly, levels of spareholding can be discussed and negotiated.

Uninterrupted availability now and into the future

UPSs exist entirely to protect other equipment, often on a large scale and running business-critical applications. Accordingly, providing protection for the UPSs themselves becomes essential. Fortunately, this can be effective provided that good quality, well-specified equipment is installed and maintained regularly, with provision for a rapid, robust response if a failure should ever occur. By following these guidelines, UPSs can offer the protected equipment’s owners and users the level of uninterrupted availability they have come to expect, now and for several years of continuous operation.

For more information of the service options KOHLER Uninterruptible Power offer, please CLICK HERE