As data centres strive for higher availability, they deploy redundancy at all infrastructure levels, from entire installations down to devices within them. Here, Alex Emms, Operations Director at KOHLER Uninterruptible Power (KUP), introduces this ubiquitous technique. He then explains how modular UPS technology can contribute to its success – while also improving power efficiency, which is another key data centre objective.

Availability at all levels

According to a recently-released Uptime Institute report, ‘Annual Data Center Survey Results 2019’, distributed resiliency using active-active data centres is becoming more common. 40 percent of those surveyed said they use availability zones for resiliency – a strategy that requires at least two active data centres replicating data to each other.

Active-active strategies are also found at server level, where they are implemented using server clustering. To clients, the cluster behaves as a single server with one IP address. While active-passive configurations are possible, where one server is online while others stand by, active-active solutions, where each node shares the workload, are increasingly preferred. These offer more computing capacity as multiple servers are available for processing, while also providing redundancy; if one server fails, the others continue servicing the critical load without interruption.

UPS installations have always supported improved availability through redundancy, even before modular designs. A 400kVA load, for example, could be supported by a single 400kVA monolithic UPS to provide capacity-only protection. Alternatively, two such units could support the load with N+1 redundancy. However, the user had to purchase double the UPS capacity they really needed, while neither unit is ever more than 50 percent loaded – and for transformer-based monolithic systems, this severely impacts operating efficiency and increases the cooling load.

The arrival of modular UPSs resolved these issues. The above 400kVA load could be met with a KOHLER PW 9500DPA rack (Fig.1), populated with four 100kVA modules – or five, for N+1 redundancy. Only 20 percent, rather than 50 percent of the total capacity is needed for the same redundancy.

Crucially, the KOHLER PW 9500DPA‘s modules can be hot-swapped, reducing repair times from an monolithic’s average of 6 hours down to typically 30 minutes. Accordingly, modular systems can offer ‘six nines’ or 99.9999 percent availability, compared with 99.9995 percent for legacy solutions.

Fig.1: KOHLER PW 9500DPA

Modularity improves efficiency too

Transformerless modular systems offer efficiency improvements over their transformer-based counterparts partly through their technology’s inherently better efficiency, but also through close matching to their critical load. Being more fully-loaded allows optimal operating efficiency.

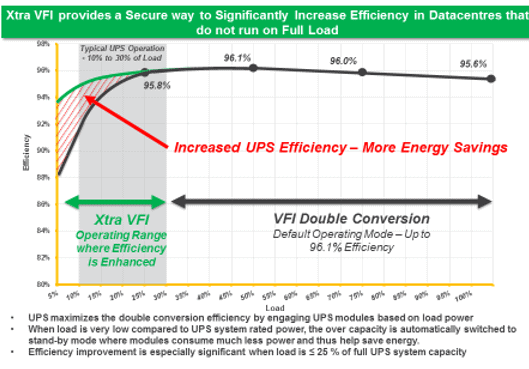

However, data centre loads can be both unpredictable and dynamic, so a UPS could become severely underloaded – and if load levels drop below 25 percent, even modular system efficiency starts falling off.

Xtra VFI technology prevents this by automatically adjusting the number of active modules to meet current load requirements. Excess modules are switched to standby, but remain primed to transfer to active mode if the load increases. Fig.2 shows how the Xtra VFI operating mode can enhance efficiency at low load levels for a KOHLER PW 9500DPA modular UPS system, with 10 UPS modules (100kW) and total available

Fig.2: How Xtra VFI improves UPS efficiency on low load

Conclusion

We have seen how modular topology improves both UPS availability and efficiency. However, to achieve these results in practice, the underlying hardware must be of robust design and construction, and professionally and regularly maintained. Accordingly, it’s essential to discuss your power protection requirements with a reputable, well-resourced and experienced supplier such as KOHLER Uninterruptible Power to avoid risk of a UPS failure and its consequences for profitability, business continuity and reputation.